Dodano do koszyka

Sprawdź również

8 percent. That`s the volume of fashion industry impact on global environmental pollution. This is more than all international flights and maritime transport together.

Taking this into consideration, the challenge for us, fashion designers, is to reduce not only CO2 emissions, but also so-called textile garbage (e.g. unused scraps of fabrics) and chemicals used in the production process. How do we approach it at KOKOworld?

Since the very beginning of the KOKOworld brand existence, we have been trying to put an equality sign between fashion and environmental care. We have been constantly looking and improving solutions that can change the fashion world for the better. And tencel appeared on our path as an outcome of such pursuits.

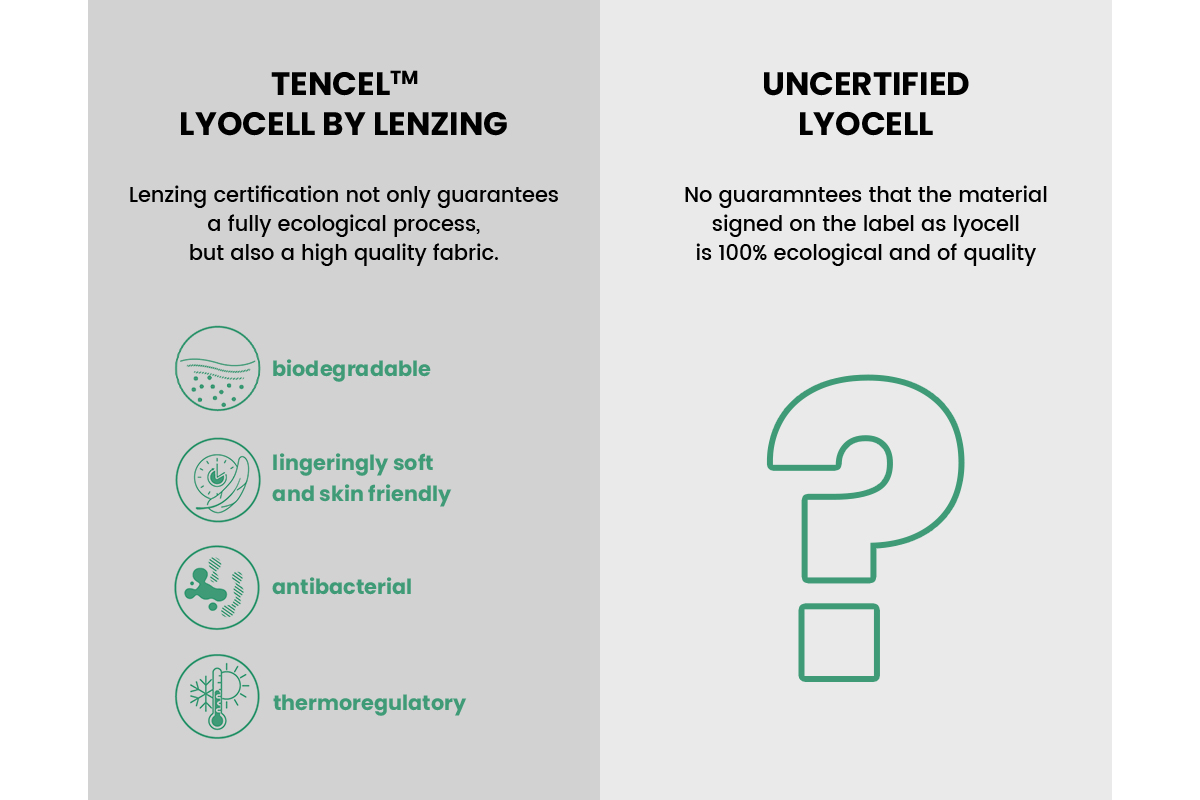

Tencel is the name of lyocell patented by Lenzing - a fully sustainable fabric obtained from wood cellulose. There are several producers of lyocell in the world, but only Lenzing mhas the right to use the name Tencel™, which guarantees the highest quality of procedures and methods for growing and producing yarn in a sustainable way. That is why in KOKOworld we have chosen this supplier.

What makes tencel a holy grail of ecofabrics for us?

Fibers that are used in the tencel production process are obtained from beech wood from certified forests with sustainable forest management.

It is very important for us because, unlike bamboos, eucalyptus or palm trees, these trees do not grow in monocultures, which means that entire ecosystems are not destroyed at the time of clearance.

The certification is of great importance, as it guarantees that every cut tree is replaced with a new tree planted. Ensuring the balance of the ecosystem is one thing, the other is to minimize the impact of transport of raw materials on the environment, therefore the distance between forests and the production spot is never more than 800 km. Isn`t it wonderful?

The entire tencel production process can be described in a nutshell as 'Less is more'.

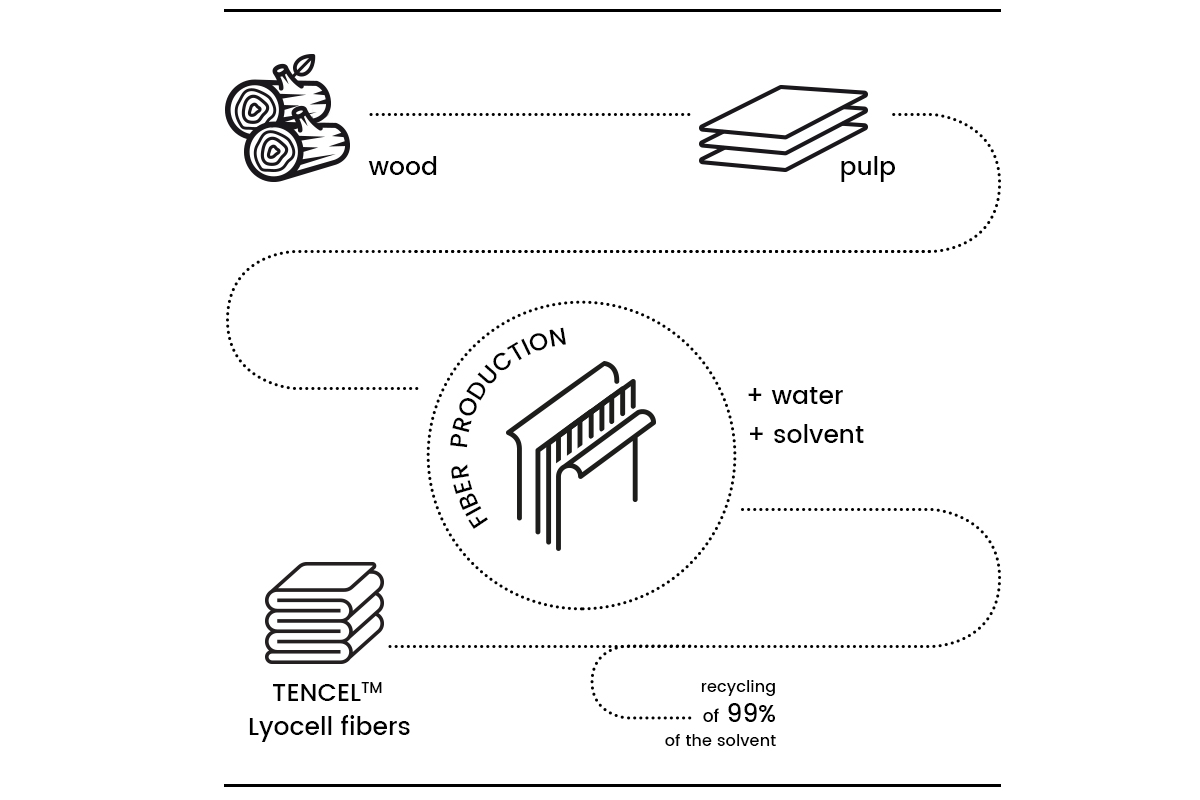

A closed production cycle allows the efficient transformation of wood pulp into cellulose fibers with low interference in the natural environment. Sounds complicated? Have a look how easy it is in practice:

Ecomagic is in the air as the solvent necessary for the production of tencel is a non-toxic substance, completely safe, and most importantly - almost 100% recyclable.

Icing on the cake of the whole process is the fact that tencel is completely biodegradable, which means that it degrades naturally and does not generate environmentally harmful substances.

Tencel has already been in the KOKOworld house for some time. There is a chance that at least one of our classic tencel gems hangs in your wardrobes - the Alhambra dress, Ararat jacket or Hebron suit.

In the former collection (spring summer 2019), we put our bet on tencel due to its unusual health and thermoregulatory properties. It is suitable fabric for sensitive skin, prevents bacteria creation and development of and is extremely sensual. It`s good to know that this fabrics cools perfectly in the summer, while in the winter it helps to keep us warm under clothing.

But the tencel uniqueness is not limited to thermal superpowers. At KOKOworld we've discovered that tencel can be an alternative to ... traditional jeans.

Up to 7,000 liters of water are used to make jeans, not to mention the amount of chemicals and energy it consumes. But still, many of us simply love jeans. It was out of this love that we were able to create our first revolutionary denim product - tencel Bosfor jeans.

It took us 5 months of hard work to create the final form of our pants, so that they resemble original jeans..

One of the most important stages of preparation process was developing a specialized fabric treatment. That includes chemicals free wash process (not to be confused with laundry) to receive the color of light jeans. The outcome?

Tencel used for the production of our eco-jeans is washed by the only laundry in Poland certified with GOTS (Global Organic Textile Standard). That is a guarantee that our projects are processed in an ecological manner, with full respect of environment

In the fall winter collection 2019 we decided to go a step further with organic denim. Our newest collection #DENIMoultion is a manifesto that proves that you can dress and act well in jeans, so hand in hand with amazing sweaters made of cotton from recycled jeans (exactly, jeans!) goes tencel - a star-billing.

As mentioned above, all KOKOworld tencel projects are made from yarn produced by Lenzing. It is important because not every lyocell on the market is Tencel™ (patented by Lenzing), i.e. material produced in an ecological manner, respecting the principles of loop process, and most importantly full of quality and customer-friendly. Therefore, Lenzing certification gis for us a guarantee that we have chosen a solution not only good for the environment, but also for us, comfortable and quality fashion fans.

Resources:

The official page of ,,The Guardian”,

https://www.theguardian.com/fashion/2018/jun/24/ten-ways-to-make-fashion-greener

[visited on the 22.10]

The official page of Lenzing company,

[visited on the 22.10]

nachhaltige Produktion

verantwortliche Materialien

Öko-Versand

14 Tage für die Rücksendung